Design of corrugated box manufacturing line

Implemented a production line that is most suitable for the factory environment and improve work efficiency.

Regardless of product requirements, Umetani can provide the most suitable production line for the factory environment through flexible and customized design.

Improving operational efficiency and more machine solutions are all considered in machine design and manufacturing.

According to customer’s machine and production inquiries, Umetani works with customers to improve their factory environment, design the most suitable corrugated cardboard production line and production process.

Process from discussion to delivery

-

STEP 01 Listen to customer and confirmation of product requirements

Confirm the size of the machine and the requirements of each machine unit.

POINT

Considering the best operational efficiency. Try to reduce the number of production steps. For example, according to mechanization, turn 3 steps into 2 steps, and 2 steps into 1 step.

-

STEP 02 Factory on-site confirmation

According to existing hardware and electrical configuration of customer’s factory, we will consider mechanical configurations that can improve operational efficiency.

POINT

Identify “improvement points” that are not easy to discover.

Factory on-site confirmation refers to discover operational obstacles to the project; and identify areas where the production line needs improvement from all perspectives. -

STEP 03 Actual introduction examples (visiting other factories)

Visiting and learning in the factories of users who have already purchased Umetani products, the actual usage and operability of the production line can be seen in detail.

POINT

After seeing the actual machine, the machine specifications can be decided later.

Umetani will provide machine design solutions, customers can compare their production lines, or ask questions and requirements directly.

Not only in the dialogue on the drawings, but also personally experiencing the actual working scene of the machine, which will have a more ideal production line and the points to be improved will become more detailed in form. -

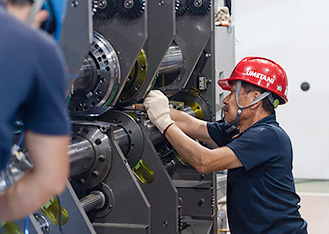

STEP 04 Introduction to Umetani Factory

Customers can visit and learn about the manufacturing process at Umetani factory.

POINT

Only through detailed confirmation of actual machines can we discover finer requirements.

From the manufacturing of parts to the assembly and trial operation of the machine, it is a continuous process, providing customers with reliable quality manufacturing conditions. Detailed confirmation can be conducted on the display machine, and finer requirements can be obtained from customers. -

STEP 05 Determine the specification

The above work includes the requirements and specifications of the machine.

The confirmation of the machine specifications, shipping schedule, and operation training will be carried out before proceeding with the manufacturing works.

Flexible design and production according to customer requirements.

Umetani has implemented flexible design in order to accurately reflect customer needs on the corrugated cardboard production line and meet customer requirements.

「You will find out that Umetani corrugator line is better than your original one and it is a reliable brand」 After having above ideas, we can proceed with machine design and manufacturing. Whether it’s customers considering a new production line or customers who have questions about the current factory issues, please be sure to discuss with us.